|

|

Versacorp Patented Axial Strut Omniramic (TM) Reflectors,

OmniLens (TM patent pending) and other Wide Angle Systems

Omnimmersion (TM) Virtual Reality Envirinments, and more.

(Some Optical Systems Available by Special Order;

Technology Transfer Opportunities Available to Licensees)

By Jeffrey R. Charles, founder of Versacorp

360 degree panoramas have been with us for decades, but taking them on a single piece of film typically involved the use of a complicated and expensive rotating camera. There had to be a better way, and the solution was right in front of anyone who had spherical ornaments on their Christmas tree: If you look directly up or down into a sufficiently curved reflector, the entire horizon can be seen as a circle! For decades, people have used hubcaps, aluminized condenser lenses, and just about anything else they could find to take wide angle pictures of the entire sky and/or horizon. When using these reflectors, most people simply placed them under a tripod. This produced a good image except for one problem; the tripod was in the picture!

Inspired by the wraparound scenery at some mountain lakes in nearby Rocky Mountain National Park, I set out to solve the "tripod in the picture" problem in 1976. The object was to obtain an unobstructed picture of the entire horizon. After considerable thought, I had a solution: a convex wide angle reflector having a central hole is positioned directly in front of the camera and lens, with its convex side away from the camera. Centered immediately behind the hole in the reflector is an optical window. Extending from the center of the window is a thin strut which holds a secondary mirror directly in front of the center of the wide angle reflector. If thin enough, the entire strut will be imaged within the image of central hole in the wide angle reflector, making it invisible in the picture! A few months later, I threw together some parts I had around the house to try out my Cassegrain axial strut wide angle reflector concept. What I built looked more like a ray gun than a camera lens, but it worked! I could use it hand held and see its image in my camera viewfinder. It was great!

One of my earliest wide angle reflector prototypes used a parabolic reflector from a projector bulb. It did not produce a really good image, but it was good enough to experiment with. A prolate aspheric reflector shape was desirable because it had less radial compression and proportional distortion than a spherical one. In early 1978, I began using the pointed half of a Chrome L'eggs "Sheer Energy" hose egg for the reflector. This produced a better image than the projector bulb reflector, but it still left something to be desired. One problem with the L'eggs reflector was acquiring a good one which was not scratched; a guy could get a lot of unwanted attention by inspecting the L'eggs display in a store! I later built a larger axial strut reflector which held the camera directly above the reflector (or vice versa) instead of using a secondary mirror. Once these axial strut concepts and designs were more refined, I patented them. Commercial Versacorp wide angle reflector systems obviously utilize high quality reflectors.

In subsequent years, I made additional improvements in my wide angle reflector systems, developed even more advanced imaging technologies, and filed additional patents. Today, Versacorp has over 200 patent claims pending for its wide angle imaging technology, with over 40 claims encompassing improvements and enhancements for my Cassegrain axial strut wide angle reflector.

At the time first I began to develop this wide angle imaging technology, converting a circular image into the traditional rectangular panoramic format (or vice versa) was possible, but it typically involved a tedious and time consuming darkroom process, one of which I invented in late 1976. The difficulty of the initial image conversion process severely limited interest in the optical system or the circular images it produced. In spite of the apparent lack of interest in circular panoramic images, I occasionally set aside time to continue improving the designs and thinking of more applications. It was one of my pet projects, and I figured it would only be a matter of time before there was commercial interest in axial strut wide angle reflectors, though I did not think it would be 20 years from the time I built my first prototype!

Fortunately, today's computer based image processing has made it much easier to convert part or all of a circular image to the rectangular format. The Adobe Photoshop program even has this capability (called the "polar coordinates" filter) built-in! Now that there is an easy way to process images, those seeking an easy way to obtain panoramic images can benefit from my 20 years of original thinking and cutting edge developments in the wide angle imaging field.

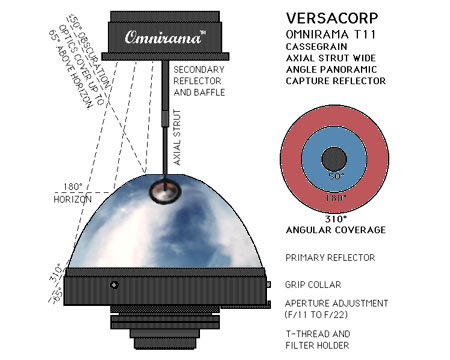

In developing axial strut wide angle reflectors, performance, portability and ease of use were my primary concerns. Remote areas can be very picturesque, and a wide angle reflector will do its owner little good if it is too cumbersome or delicate to be used in the field. Durability is also a concern when the reflector is used in a crowded or unsupervised area. Accordingly, while continuing to develop new reflectors, I have continued to emphasize at least one rugged and highly portable design. The newest version of this compact and easy to use axial strut panoramic imaging system is particularly well suited for still photography and electronic imaging with 35 mm and similar format cameras. It is called the Omnirama (TM) T11.

The T11 is only 12.5 cm (5") in diameter and 21 cm (8") long - small enough to go anywhere! It can be used either on a tripod or hand held in any orientation. Used vertically, it will record an entire 360 degree panoramic image in a single shot! The vertical panoramic coverage exceeds from 55 degrees below the horizon to 55 degrees above. In addition, the T11 is a complete integrated system rather than an attachment for the front of a camera lens - just put it on your camera like any other lens and shoot! It has industry standard "T" threads which allow it to be used with virtually any 35 mm camera. Even though the T11 reflector system typically works best when used at moderate f/ratios, (f/11 or slower) its portability and ease of use make taking 360 degree panoramas a truly casual and enjoyable experience!

Another advantage of the patented Versacorp Omnirama Reflector system is its affordability. Many versions are substantially less expensive than a rotating panoramic camera, while being far easier to set up and use! In addition to the T11 system, Versacorp offers special order axial strut and other wide angle reflectors for a variety of formats and applications, as well as providing custom assemblies and consulting services for wide angle imaging, projection, simulators, surveillance, robotics, autonomous flight control, defense, space missions, and other applications.

Nearly all reflector systems will be made to order, (at least until it is

determined which models become the most popular) so most items have relatively

long delivery times. This "made to order" situation facilitates

modifications for specific customer applications. Prices, specifications,

and availability are subject to change without notice. Versacorp does not

presently market image processing software due to the variety of excellent

programs already on the market, though it may later offer software (patent

pending) based on its previous patented darkroom based panoramic conversion

techniques. Please direct inquiries to the Versacorp Omnisales (TM, SM)

department: (sales *at* versacorp.com).

Return to Local Table of Contents

In addition to its regular products, Versacorp can supply a wide variety of specialized custom made wide angle optical systems for various customer and OEM applications. Most low volume systems utilize reflective optics since they typically have lower NRE and tooling costs than do all refractive systems. In order to assist customers in making their own cursory feasibility studies, some basic technical information is provided below. It addresses a few of the trades which must be considered in the design of reflective wide angle systems. There are a number of issues to consider when selecting a wide angle reflector. Many of these are interrelated, but for the sake of simplicity, only one description of each factor will be paired with each requirement in the brief analysis below.

One of the first things one needs to do is define what the actual requirements and prioritize these above other issues that are merely goals or mild preferences. To start out, it is useful to list the questions for which the answers would define one's requirements. A few basic questions include:

1.) Is your emphasis on panoramic format images that are viewed (typically by panning) from a virtual center, or on full sphere images that are viewed from multiple vectors and orientations in all three dimensions?

2.) What vertical coverage do you need in a 360 degree panorama? Full sphere 360 x 360 coverage (viewed as a 360 x 180 degree panorama or from multiple vectors of a sphere) has its very unique uses, but there are some cases where full sphere coverage may not buy you much more than would something like 360 x 310 degrees of coverage which has some central obscuration (viewed as a 360 x 130 degree panorama that covers from about 65 degrees downward to 65 degrees upward). For example, a 360 x 360 degree image (viewed as a 360 x 180 panorama) will cover from straight "up" to straight "down", but if the subject is the interior of a building having plain carpet and a featureless ceiling, the area immediately surrounding straight up and down vectors will have no special features. In this case, you may not need to have full sphere coverage. If, on the other hand, you are imaging an interior having an ornate ceiling and an interesting floor surface, you could benefit from as much as full sphere coverage.

3.) What resolution is required? For example, do you only need enough resolution to get a good full screen panorama on a computer, or do you want to see only part of the panorama at once, or need to "zoom in" a little on a feature without photographing it separately? If you will need to zoom in, Is there a limited vertical zone in your panorama (e.g. directly to the side, or some angle above or below this) at which your resolution requirements are greater? These issues drive cost and physical size.

4.) Do you only need to capture still images, or are full motion panoramas (or full sphere images) also a requirement?

4a.) If full motion panoramas are a requirement, do they need to be captured in subdued light?

4b.) If full motion panoramas of dim subjects are a requirement, what is the slowest acceptable frame rate?

4c.) What are the resolution requirements for full motion panoramas or full sphere images?

4d.) Do you need to record sound that is synchronized with full motion images?

Answers to these questions will drive the cost and physical size of a system to a very significant degree.

5.) What environment will the system be used in? For example, indoors, outdoors, in the rain, around crowds, attended or unattended, etc.

6.) What is the maximum physical size the optical assembly can be for your applications?

7.) What is the physical size of your camera? For contiguous full sphere original images, the physical size of the lens assembly must be large enough to "see around" your camera. This is not a requirement when the final full sphere image is made up of more than one original.

8.) Does your camera have a removable lens or a permanently attached one?

9.) Do you need a turnkey integrated hardware and software solution, or will you be using separate software resources to process your images? In many cases, the need for an integrated system will be determined by the volume of images you are working with, and will have some influence on cost, etc.

10.) Do you need 3D images or 2D images with 3D information? If so, do the 3D images need to be observable as 3D in orientations other than the normal "right side up"?

11.) What are the required quantities and acceptable price limits?

Following are some technical considerations for angle of view and other attributes.

ANGLE OF VIEW drives requirements for the amount of curvature a reflector must have. This in turn drives factors such as the maximum f/ratio that can be used with a given reflector diameter. Depending on the reflector design, the maximum angle of view can exceed 350 degrees, but there is typically a diminishing return in terms of cost, portability, and/or performance when the angle of view exceeds 280 degrees or so (50 degrees below the horizon when an upward pointing reflector is used).

CENTRAL OBSCURATION of a reflector system also affects the angle of view. For an upward pointing reflector, the limit of coverage above the horizon is determined by the reflector's central hole and/or any obstruction above it. Requirements for coverage too near the zenith can restrict the maximum f/ratio which can effectively be used with a two reflector "Cassegrain" system in particular. The diminishing return in regard to cost, f/ratio, and portability begins at apparent central obstruction diameters below about 70 degrees for most two reflector systems and 20 degrees (depending on camera) for single reflector systems.

OPTICAL FIGURE considerations can provide additional degrees of freedom. If an unusual reflector figure (i.e. a figure other than a typical continuous spherical or aspheric figure) is used, the central obscuration angle can be reduced without necessarily reducing the maximum f/ratio. Proprietary Versacorp radially offset, torroidal, and other atypical wide angle reflector figures (patent pending) allow the central obscuration angle to be reduced or even eliminated. These unusual reflectors will produce images with slightly greater proportional radial compression than a conventional aspheric reflector, but this is not a problem in cases where the image is to be converted to a conventional rectangular or VR format. The widest version of the Versacorp T11 panoramic imaging system uses an unusual radially enlarged reflector figure (patent pending) to achieve its unprecedented 130 degree vertical panoramic coverage. Unusual reflector figures can also be used to increase the radial image scale of a given zone of the image to achieve emphasis and/or higher resolution.

PROJECTION, or more particularly off-axis imaging characteristics, drive the shape of the reflector and/or the optical distance between it and the camera. These factors will determine the enlargement and/or radial compression of the proportions of the off-axis image. An oblate ellipsoid (similar to the shape of a metal Revere Ware (R) pan lid) will typically produce the most radial compression, a sphere will produce moderate compression, and a hyperbolic reflector will produce the least. Generally speaking, it takes a "taller" reflector to reduce radial compression, which in turn requires the imaging lens to have more depth of field. The effective distance from the camera to the reflector also affects off-axis imaging. A closer camera distance will typically result in a higher degree of radial image compression with a given reflector. Another consideration is cost. A spherical surface is the easiest to produce, but it has a relatively high amount of radial image compression. The radial compression can be compensated for with image processing, but this may result in some loss in vertical resolution in the part of the subject that is below the horizon.

RESOLUTION requirements in turn drive requirements for the surface quality and diameter of the reflector, though the diameter can be reduced in cases where a field flattener is used. This factor can also affect the maximum practical f/ratio. As with all imaging, it may be necessary to utilize a larger format film camera (and a longer focal length optical system) or an electronic sensor with more pixels to obtain extremely high resolution.

MAXIMUM F/RATIO drives requirements for the minimum acceptable reflector diameter, though the diameter can be reduced in cases where special correcting lenses and a field flattener are used. The virtual image of the reflector is curved, so a camera lens producing the real image must have a properly curved field or sufficient depth of field. In the absence of specialized corrective optics, the use of a moderate f/ratio will be required to achieve high resolution over the entire field. For a conventional 50 mm imaging lens used with a 35 mm camera, this maximum f/ratio may range from f/4 or f/5.6 for a large reflector to f/11 or f/16 for a small reflector. Generally speaking, the smaller the image format, the larger the allowable f/ratio with a given reflector. Wider apertures can be used if high resolution is only critical near the horizon or another selected zone of the image, or if the system includes a field flattener. Relatively inexpensive singlet field flatteners are typically the most effective when used near the focal plane, so their use typically indicates the use of a film or electronic sensor back instead of a complete camera. Versacorp does not presently offer field flattener / film back combinations; however, assemblies suitable for use with custom Versacorp reflectors and axial strut kits can probably be fabricated from items provided by various camera and optical suppliers.

ENVIRONMENT can drive how rugged and/or portable a reflector must be. Top of the line Versacorp reflectors are designed to provide good protection for the delicate reflector surface. Reflector substrate materials can include glass, metal and plastic. Glass is good for many applications but is not very economical when the surface accuracy must exceed that achievable with a fire polish. Metal (including aluminum, nickel, or steel) is typically best for durability and resistance to thermal shock. Plastic is typically best for economy but can be more easily damaged. Reflective coatings can differ according to the application can be used. Protected Aluminum or Enhanced Aluminum are typically used in applications requiring high reflectivity. Due to its durability, Rhodium is used for most other applications within the visible and near IR spectrum. Coatings can be applied by various means, including vacuum deposition (as is commonly used for glass telescope mirrors) or by plating techniques such as electrolytic replication (which is commonly used for metal reflectors).

Additional technical information can be gleaned from the references in the "recommended reading" section.

Do you have wide angle imaging requirements that are not addressed in this material? Versacorp offers appropriate engineering services.Return to Local Table of Contents

Portability and ease of use are important characteristics for any piece of fine photographic equipment. As is the case with most optics, the physical size of a wide angle reflector can typically be reduced if the overall system has a slower maximum f/ratio. Large wide angle reflectors can be used effectively with 35 mm and other film cameras, video cameras, and digital still cameras, but a larger reflector is typically only necessary when a fast f/ratio is required. If a fast f/ratio is not required, the added weight and vulnerability of a large reflector presents an unnecessary burden. Fortunately, except in cases of where a moving subject must be photographed in subdued lighting, moderate f/ratios (and smaller reflectors) are acceptable for wide angle photography. Therefore, Versacorp has developed and patented (U.S. Patents D312,263, 6,333826, and patent pending) the compact and versatile Omnirama (TM) T11 axial strut wide angle reflector.

The T11 is only 12.5 cm (5") in diameter and 21 cm (8") long - small enough to go anywhere! It can be used either on a tripod or hand held in any orientation. In addition, this particular model is a complete integrated system rather than an attachment for the front of a camera lens - just put it on your camera like any other lens and shoot! It has industry standard "T" threads which allow it to be used with virtually any 35 mm camera. Other configurations include "afocal"' versions of various sizes that can be used in front of the fixed or zoom lens of a video camera or digital still camera. These include special "afocal"' optical modules that facilitate use of the T11 on cameras having permanently attached lenses.

When the T11 is pointed straight up or straight down, its precision convex aspheric primary reflector images a 360 degree Omniramic (TM) panorama of the entire horizon (in annular form) with extraordinarily wide vertical coverage; from 55 degrees below the horizon to more than 55 degrees above. The T11 model W covers from 65 degrees below the horozon to 65 degrees above (310 degree AOV with a 50 degree central obscuration), and custom versions can cover from 65 degrees below the horizon all the way to as far up as straignt overhead (310 degree AOV with down to no central obscuration).

With the innovative Omnirama T11 axial strut wide angle Omniramic (TM) reflector system, you can instantly capture an entire 360 degree panorama with the ease of taking an ordinary snapshot. It can even be used with a hand held camera!

The compact T11 reflector works best when used at moderate f/ratios (f/16 or slower with 35 mm cameras; f/8 or slower for smaller digital cameras) but its portability and ease of use make capturing immersive 360 degree panoramas a truly casual and enjoyable experience! You can use it for many applications, including interiors, exteriors, conventions, weddings, unique group pictures, balloon flights, solar eclipses, and mountain scenes. A half scale (at 72 dpi) drawing of the Omnirama (TM) T11 (U.S. Patent 6,333,826) is shown below.

|

Versacorp Omnirama T11 Immersive Imaging Reflector Specifications:

* In versions providing a 23 mm image circle, the maximum recommended transmission value is equal to f/16; the f/ratio is actually f/13.3. The T11 also has an f/11 setting which can be used for composition and lower resolution panoramic imaging with slightly less vertical coverage. Faster f/ratios are available for suitable digital cameras and sensors, owing to their smaller image circle requirements.

Either model of the Versacorp Omnirama (TM) T11 includes a carrying case; an EZ Level (TM) level indicator (visible in some camera viewfinders and from above and below the T11; U.S. patent 6,333,826); a Sun Zapper (TM) positionable solar occulting sphere (with about a 3 degree apparent angle; U.S. patents 6,333,876 and 6,449,103) to reduce flare from direct sunlight; and a combination tripod "L" bracket and triggerless pistol grip (to keep your tripod out of the picture and put your vantage point above the crowd).

Optional accessories include a central rain shield (90 degree overhead obstruction); a clear plastic storage tube (which can be left on for composition and removed for taking the picture); and a precision heavy duty T-ring for Nikon (machined from the Nikon reversing ring). (Versacorp does not sell other T-rings. T-rings are available at most photo stores).

Pricing: Versacorp is offereing technology transfer opportunities to parties interested in purchasing licenses for this and related technology. However, while Versacorp holds the license, the Omnirama T11 can, under some circumstances, be acquired (typically in quantity) by special order. The unit price for low quantities (as available) is $3,795 and can be substantially lower for large quantity purchases. The T11w is currently the baseline version. Inquiries are invited from technical instrumentation representatives and from camera and scientific supply dealers. Custom configurations (including a an even wider field of view and "non-Cassegrain" versions) are available as special order items. Delivery (particularly of special order versions) is typically expected to be from 90 to 180 days from receipt of paid order, though this can often be expedited if a sufficient quantity of identical units is ordered at the same time.

Versacorp has a patent (U.S. 6,333,866) and patent pending for image processing techniques which are envisioned to be incorporated into software which can expeditiously convert annular images produced by the T11 into conventional viewing formats for still and motion images and for recreation and simulation of other envirinmental effects. It may be some time until this software is introduced. In the mean time, photographers can use image processing tools such as the "polar coordinates" filter in Adobe Photoshop to manually accomplish similar results with each image frame.

Technical inquiries relating to the Omnirama T11 and other Versacorp products may be directed to Jeffrey R. Charles: (jcharles *at* versacorp.com). Inquiries relating to licensing Versacorp technology may be directed to the Technology Transfer Department: (license *at* versacorp.com).

Additional products and technologies: Versacorp offers other products as well as custom made items and related engineering services. A few specific products and applications are addressed below.

Need more than 110 degrees of vertical coverage? The compact T11 model w axial strut wide angle reflector (patent pending) covers from 65 degrees below the horizon to 65 degrees above (310 degree angle of view with only a 50 degree central obscuration); and you get all this extra coverage at no extra charge! Imagine instantly capturing a 360 degree panorama with 130 degrees of vertical coverage - all with the ease of taking an ordinary snapshot! You need not imagine any more; order the Omnirama T11 today start experiencing the Reality of Virtual Reality! (TM, SM)

Need complete "full sphere" coverage? Check out the Versacorp (TM, SM) OmniLens (TM) in the "New Technology " section. For neary full sphere coverage, check out the Versacorp Omniflector (TM) and other optics in the "Other Panoramic Products" section.

Need a faster f/ratio or want to utilize a larger format? If you need a reflector which can be used effectively on a 35 mm camera at a faster f/ratio than f/11 or if you want to use a large format camera, a system with a larger reflector and/or specialized correcting and field flattening optics will be appropriate. Versacorp can supply these systems on a custom basis.

Need a large quantity of wide angle omniramic systems for a really low price? Versacorp can provide low cost fixed aperture plastic versions of the T11 (U.S. patent 6,333,826 and patent pending) or its other products to those ordering several hundred units. While a plastic version of the T11 is not as durable as the conventional model, its imaging performance is almost as good and it can cost as little as a few hundred dollars per unit! Smaller video systems can cost even less!

Have digital imaging, video, or motion picture applications? Versacorp can readily adapt the T11 axial strut reflector system to many of these applications. Most of these adaptations involve very reasonable charges for engineering and custom fabrication, including fabrication of special interfaces and configurations. If your sensor or film format is relatively small and your instrumentation will allow the use of optics having a moderate back focal distance, then the compact T11 (TM) system can be provided in versions that work at substantially faster f/ratios and/or even have smaller reflectors. It is even possible to adapt it to some fixed lens cameras with a Versacorp "afocal" VersaModule (TM) optical module! For more options, please check out the related subject matter elsewhere in this document.

Even more stuff! If a camera (or reflector) is sufficiently small and light, the camera can be mounted directly in front of a single convex reflector via an axial strut. This patented design (U.S. Patents D312,263 and 6,333,826) can radically reduce cost, while reducing the central obstruction to as little as 15 degrees! (Still other versions (patent prnding) have no central obscuration at all!) This "camera in front" design is not always as convenient to use as the dual reflector T11, but it has its merits where a fast f/ratio is required. Since the camera (and the photographer, if present) are in the center of the image, it is best to utilize a self timer with this version. Versacorp offers custom wide angle reflector systems as well as axial strut components and assemblies which can be used with existing reflectors. Versacorp does not presently offer a "standard" model of a large reflector system, but it may do so if there is adequate demand for it. This "camera in front" design and the axial strut components are further addressed in the following sections.

Versacorp can provide wide angle optical systems and technologies for other applications including aerospace, medical imaging, robotics, simulators, monitor and control systems, surveillance, omnidirectional VR projection systems, VR games, and more! Please inquire about your specific requirements.

Return to Local Table of Contents

Medium and large format cameras typically have longer focal length "normal" lenses than do 35 mm cameras. This results in a comparatively large physical aperture diameter at a given f/number. This in turn causes more of the reflector to be involved in imaging a given point in the subject, increasing the reflector's relative surface accuracy requirements. In addition, a larger image of the reflector is required to utilize the larger film format. This necessitates a focusing the camera lens for reproduction ratio closer to unity, which in turn limits depth of field and necessitates stopping the lens down and/or using an expensive field flattener to get a sharp overall image. In the case of an 11 cm reflector used with a 6 x 6 cm or 6 x 7 cm camera, an f/ratio of 16 or slower would be required to get even a reasonably sharp overall image.

The most elegant way to solve the medium format problem is to use a larger reflector, and Versacorp can offer large made to order reflector systems. Systems are envisioned for various medium format cameras, with an emphasis being placed on Hasselblad cameras having digital or film backs. It is anticipated that this system will be adaptable to the Pentax 6 x 7 cm camera in order to take advantage of this camera's superior compatibility with hand held use. A "standard" medium format model may be offered at a later time if there is adequate demand for it. In addition, Versacorp offers engineering services and custom made adjustable length axial strut and optical window kits and assemblies which allow customers to utilize existing reflectors.

It is important to note that many of the high resolution advantages of medium format can be realized by using a relatively small electronic imaging sensor having a high pixel resolution. This in turn allows the overall imaging system to be relatively compact. Versacorp has been in communication with manufacturers of still and full motion high resolution electronic camera systems regarding a synergistic combination of Versacorp optical systems with existing and future electronic cameras.

Return to Local Table of Contents

Motion picture and video applications present unique challenges for wide angle imaging. The cameras (particularly professional units) can be quite heavy. In addition, the plastic lens barrels on the lighter consumer equipment may not be physically strong enough to reliably support a reflector which is attached via filter threads. These factors typically require a relatively sophisticated camera/reflector interface bracket. In cases where the camera is used in front of (and above) the reflector, the axial strut must often be relatively large in order to provide adequate stability. In cases where the camera is used below the reflector, the reflector must be light enough to prevent excessive stress on the camera lens barrel. In cases where the camera is used behind the reflector with a dual mirror system, the camera or reflector support must not stress the lens barrel.

An additional challenge is presented by fact that there are practical limits to how much the shutter speed or integration time can be increased for low light conditions. This can result in the need for a faster f/ratio, which will result in a reduction in depth of field for imaging the reflector. This in turn will require the use of a larger reflector, a potentially expensive field flattener, or a corrected system such as the Versacorp Omnirama T11 (TM) or OmniLens (TM).

Yet another challenge is presented when auto iris zoom lenses are used. This requires the geometry of the system to be compatible with the full aperture range of the zoom lens, which in turn tends to increase the relative diameter of the window, thereby increasing the centrally obstructed angle. Cameras which have interchangeable manual iris fixed focal length lenses do not tend to have this problem, but comparatively few of todays cameras accept interchangeable lenses.

Most video and motion picture zoom lenses require a clear optical window aperture in excess of 3 or 4 cm. This in turn requires the use of a relatively large primary reflector for a two mirror system (i.e. one which places the camera behind the primary reflector) if the central obstruction is to be reasonably small. Therefore, appropriate reflectors for most two mirror motion picture and video reflector systems will be similar to those for medium format cameras.

Digital still cameras tend to be lighter than video cameras, but most of these only provide an image every few seconds rather than true full motion images; however, such cameras are obviously suitable for some webcam applications. A few relatively modern high resolution digital cameras will provide full motion images. These typically have relatively large image sensors, so they can be used with or adapted to Versacorp optics which are optimized for film cameras.

In the case of imaging with smaller consumer digital cameras, film cameras, and camcorders (i.e. "palmcorders "), an elegant solution for many applications is to place the camera in front of a single convex reflector. This radically reduces cost and the required size of the reflector, while reducing the central obstruction to as little as 15 degrees! The camera can be conveniently set up with the use of a small LCD monitor.

Systems for small digital, video, and film cameras can be made with the use of items in the "Modular Axial Strut Components Sans Reflectors" section. While the appearance of a moving wide angle reflector image is novel, video and smaller motion picture formats do not offer high enough resolution for truly realistic VR applications. Accordingly Versacorp does not currently offer a "standard" integrated motion picture and video reflector system, but it may offer one at a later time if there is adequate demand and/or a given format becomes more widely used for ultra wide angle imaging. For wide angle imaging solutions, please inquire concerning your special applications.

If your video or motion picture camera accepts standardized interchangeable lenses (such as C-mount) and you do not need a particularly fast f/ratio, adaptations of the compact Versacorp Omnirama T11 reflector system may serve your needs, as may some of the miniature optical systems (U.S. Patents 6,333,826, 6,449,103 and Patent Pending) referred to in the New Technology section. Please inquire if interested in these optical systems or licensing the related patented technology.

An additional possibilities include the use of a close-up lens or "afocal" optical module such as the VesaModule (TM) afocal module (U.S. Patents 6,333,826 6,449,103 and patent pending) to adapt an existing optical system to a fixed lens camera. Please inquire if you are interested in any of the above options or if you have a special requirement for which a custom system may be necessary.

Return to Local Table of Contents

Many customers may have specialized needs for panoramic imaging, surveillance, and other applications. Accordingly, Versacorp offers customized fixed and adjustable length axial strut, optical window, and secondary mirror kits which allow customers to utilize existing reflectors. Useful reflectors include larger versions of popular plastic surveillance hemispheres. All the customer has to do is cut or drill a hole in the front of the reflector and provide suitable means for mounting the strut.

One version places the camera in front of the reflector and the other includes a secondary mirror which allows the camera to be behind the reflector. In the case of the latter system, customers can install a video surveillance system inside of better existing surveillance reflectors. Versacorp can also supply custom centrally bored surveillance reflectors and unitized systems (sans video camera). These custom items are only available on a prepaid order basis.

Versacorp axial strut kits are offered in a variety of sizes. All must be used with the customer's reflector, camera, and "normal" (or nearly normal) lens. The least expensive versions utilize thick Plexiglass (R) windows at one end of the strut. Prices are by quotation, but a few are indicated below in order to give you a "ball park" idea about how much the simpler embodiments in each category may cost. Please specify camera, lens, application, intended reflector, and maximum f/ratio requirements when inquiring. Customized and standard parts which are offered or are envisioned to be offered include:

Have wide angle imaging needs which have not been addressed in this material? Versacorp offers appropriate engineering services.

Return to Local Table of Contents

Versaflector (TM) Reflectors and Fixtures for Use With Remotely Positioned Cameras

Versaflector (TM) wide angle reflectors (U.S. Patents 6,333,826, 6,449,103 and patent pending) are "stand alone" wide angle reflector systems which can be strategically positioned for surveillance, documentation, general photography, and other applications. They are best utilized by imaging them with a long focal length lens and from a great enough distance (typically 1 to 10 meters) that the camera appears relatively inconspicuous in the reflected image. The Versaflector (TM) fits standard 1/4 - 20 tripod threads and Versacorp can supply additional accessories to allow easy adaptation to microphone stands, doors, light fixtures, and other supports.

This system can accommodate spherical and aspheric reflectors, some of which will cover more than 350 degrees. A prototype of this system (which was attached to the edge of an open door) was used in 1978 to take the 350 degree indoor image shown in the paper by Jeffrey R. Charles on Polar and X-Y Projection Omnidirectional Images and related techniques for digitally converting panoramic images between either projection with Adobe Photoshop. (U.S. Patent 6,333,826 and a pending patent apply to some of the correction techniques covered in this paper.)

Please feel free to contact Versacorp for more information about Versaflectors or other wide angle imaging solutions.

Need a reflective panoramic imaging system with even more coverage? Versacorp Omniflector (TM) reflectors can cover nearly an entire sphere! Most of these made to order items position the camera in front of the reflector, but two mirror technolgy is utilized in some versions. The two reflector systems are similar in appearance to the T11 reflector except they are usually larger and proportionately taller.

Want even more coverage? The Versacorp OmniLens optical system covers an entire sphere! Check out the "New Technology" section.

Want to know more? Contact Jeffrey R. Charles (jcharles *at* versacorp.com) or read the references listed in the last section of this document.

Have wide angle imaging needs which have not been addressed in this material? Versacorp offers appropriate engineering services.

Return to Local Table of Contents

New Technology - True Omnidirectional (>360 Degree) Optical Systems

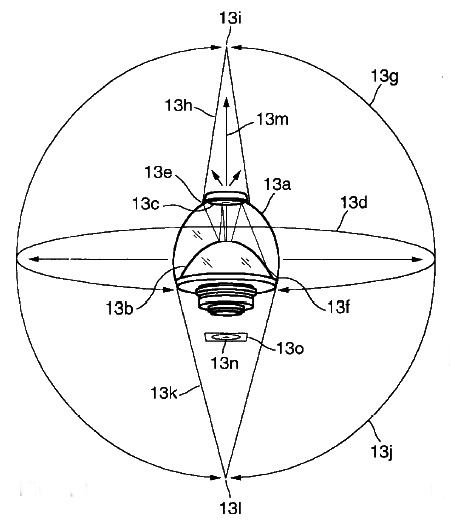

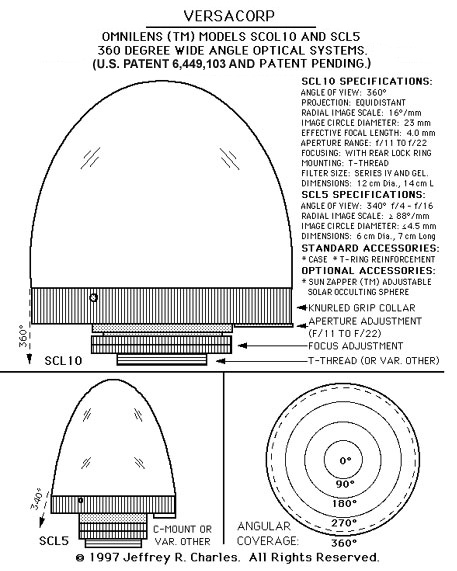

Versacorp has developed the OmniLens, (TM) (U.S. Patent 6,449,103 and Patent Pending) a TRUE OMNIDIRECTIONAL OPTICAL SYSTEM that captures the entire sphere around itself in a single image. It can literally "see" behind itself! This very unique, durable and versatile optical system is truly on the "cutting edge" of modern technology. It can be manufactured in a wide variety of sizes; from micro miniature on up, making it applicable to many applications including aerospace, medical imaging, panoramas, surveillance, VR, video, machine vision, micro assembly, inspection, measurement, motion detection, switching, robotics, simulators, monitor and control systems, autonomous vehicle and flight control, and projection systems. OmniLens images can facilitate VR applications in which one can literally "look" everywhere, including straight up and straight down!

The OmniLens is so compact, practical, and affordable (particularly in quantity) that it may become the new standard in wide angle imaging! For some applications, it may even supplant the innovative optics shown elsewhere in this document, and it could easily become a high volume product. It is mechanically rugged and can be made relatively resistant to thermal shock, making it useful for a variety of commercial and aerospace applications.

|

Patented OmniLens (TM) technology is also applicable to optics having a more reduced field of view. Models which cover about 320 degrees are even more compact and affordable than the 360 degree versions. The 320 degree OmniLens for a 35 mm still camera is about the same diameter as the Versacorp Omnirama T11 wide angle reflector. Embodiments (including afocal models) for digital and video cameras can be even smaller. Most version include a patented integrated level indicator or are compatible with Versacorp level indicator attachments.

Systems which cover a still smaller (yet still very wide, compared to the competition!) field of view and have a modest central obscuration angle can be even smaller and more affordable. A unit having a 60 degree central obscuration angle and a 300 degree angle of view will image a great circle around its optical axis and about 60 degrees on either side, providing a 360 degree circular panorama with about 120 degrees of vertical coverage.

Technical inquiries relating to the OmniLens and other Versacorp products may be directed to Jeffrey R. Charles: (jcharles *at* versacorp.com).

Your company can benefit from OmniLens technology! Versacorp, being primarily an engineering service business, has determined that it will offer licensing for OmniLens technology rather than orchestrating all OmniLens production and marketing itself. (However, special quantity orders of prototype and production systems are welcome.) Please direct licensing or partnership related inquiries to the Technology Transfer Department: (license *at* versacor.com).

A few versions of the OmniLens are shown below, minus a few details. At 72 d.p.i., the drawings are about 80 percent of actual size. The top drawing figure shows the system in its smallest practical size for 35 mm photography with a conventional camera. A larger version is required if the final image is full sphere and it must exclude all parts of a popular SLR camera. The Omnilens system is also applicable to lesser angles of view, and to use in a reversed orientation (e.g. where its primary reflector faces the camera). The lower left figure shows a 340 degree version of the OmniLens for C-mount movie, video, or digital cameras which can also be attached to a VersaModule (TM) afocal adapter (as can most other versions) for use on fixed lens cameras.

On some versions, the "standard:quot; rear section is interchangeable to facilitate adaptation to various video and digital imaging formats as well as to "afocal" applications where the optics are installed in front of an existing camera lens (including a non-interchangeable camera lens). The lower right figure illustrates an equidistant (constant radial image scale) 360 degree image projection. Other radial image distributions are available. Most OmniLens systems having a more modest angle of view are substantially shorter, with some having a length far less than their diameter.

|

Versacorp OmniLens technology is applicable to panoramic imaging, full sphere imaging, webcams, surveillance, weatherproof and weather resistant imaging systems, laparascopic medical instruments, machine vision, robotics, flight control, underwater imaging, motion sensing, and other systems. It can also be particularly useful for space missions (including manned and robotic lunar or interplanetary missions) or other applications where using a fixed optical system to image any and all parts of the surroundings would be advantageous. Some newer OmniLens technology will even image in 3D!

Whether used alone or with real time digital image processing, the OmniLens is a powerful tool which can enhance existing surgical techniques as well as enabling new medical and other procedures which heretofore may not have been possible. OmniLens "Immersion" systems are optimized to provide the maximum field of view when immersed in liquid. Miniature versions of the OmniLens can be very economical in large quantities and can be incorporated into instruments such as proposed Versacorp VersaScope (TM) laparascopic instruments, borescopes, surveillance instruments, catadioptric microscope objectives, long distance microscopes, telescopes, and related VR production, presentation, and software environments.

As is the case for larger versions, the OmniLens optical system is applicable to both omnidirectional coverage and to optics having a lesser field of view. Lower cost OmniLens designs can be employed where true omnidirectional coverage is not required. The OmniLens is applicable to both direct imaging and afocal configurations, so it can either be an integral part of OEM instrumentation or an attachment for existing instruments. The OmniLens can be particularly economical in quantity.

Have specialized wide angle imaging requirements which are not specifically addressed in this material? Versacorp offers appropriate engineering services.

Return to Local Table of Contents

Indexing Rotary Camera Platforms and Other Panoramic Products

Need extraordinarily high resolution? The best way to get the really high resolution which will allow substantial enlargement of smaller sections of a VR or other panorama is to have a large original image scale. This usually means taking panoramas the "old fashioned way", as a series of pictures. In order to make this process easier, Versacorp offers the Versarama (TM) Indexing Rotary Camera Platform, a system initially developed (by Versacorp founder Jeffrey R. Charles) for quickly taking high resolution 360 degree panoramas at the 11 July, 1991 total solar eclipse - one of the most challenging subjects in nature!

|

|

The basic Versarama (TM) motorized platform can be configured to automatically stop at predetermined (and in some models, user configurable) intervals that are divisible by 22.5 or 30 degrees, making your panoramas a snap (or a series of snaps!) Now you can shoot high resolution VR images from unusual or remote vantage points! Put your VR vantage point above the crowd with the Versarama indexing rotary camera platform! The basic Versarama motorized platform is priced from only $995.

For even easier panoramic sequence photography, Versacorp offers the Deluxe Versarama (TM). This proprietary platform has all of the features of the basic Versarama and even more, including the instant selection of "stops" at 12, 15, 18, 22.5, 30, 36, 45, 60, 72, and 90 degree intervals. Additional user configurable features facilitate 120 and 180 degree intervals. The base of the unit includes a shutter release button and a commutated connection for an electronically actuated camera shutter release. (This provides more continutiy than the rotate 360 then return attributes that can be enabled on the standard version to prevent cable wrap.) Just push one button to take a picture with your motor drive camera (and its electronic release adapter cable) and push another button to rotate the camera for the next shot. What could be simpler! Optional accessories include a remote control hand paddle and a variable speed automated control module which can make the platform and your camera shoot and rotate automatically, either on a continuous basis or automatically stopping (and returning to its home position, if necessary) after one full rotation. The Deluxe Versarama starts at $1,795. This capable technology is also available for license.

Other Versacorp panoramic imaging products include consulting and the other systems shown on this web page.

Return to Local Table of Contents

Versacorp has developed image distribution, display and projection concepts and systems (U.S. Patents 6,333,826, 6,449,103 and patent pending) and related optical systems (patent pending) that facilitate omnidirectional or nearly omnidirectional (depending on cost) projection systems and Omnimmersive (TM) virtual reality environments. These systems are capable of facilitating a total immersion VR experience which can encompass far more than visual effects.

Omnimersion (TM, SM), which completely surrounds participants in an Omnimersive (TM) environment covering up to a full sphere, as well as Total VR and Total Immersion VR (TM), which surround participants with one or more 360 degree Omniramic (TM) environments, could become the new standards for monotoring, control, training, and entertainment VR applications. The systems were initially developed to simulate the experience of observing a total solar eclipse, but they are applicable to many other fields, including those where participants are suspended or otherwise positioned near the center of the projection area.

In most cases, entire Total VR (TM) and Omnimersion (TM, SM) systems are not deliverable prefabricated "products". They are typically systems which can be integrated into existing theaters, businesses, homes, or other structures which are appropriately modified. Omnimmersion and Total VR systems are applicable to large theaters, but most versions are best suited to small single or multiple portal (i.e. single or multiple room) VR projection suites or entertainment systems which are occupied by anywhere between one person and a few dozen people; in which participants are free to sit, stand, or move around. Some versions of complete portable omnidirectional display systems can probably be provided within several months after receipt of a paid order. Smaller systems can utilize selected existing single lens LCD projectors, and most of them require only one projector source!

Versacorp continues to develop leading technology. One of the newest additions to Versacorp Total Immersion (TM) VR system technology is an optical system (U.S. Patents 6,333,826, 6,449,103 and patent pending) capable of 3D omnidirectional imaging and projection (alternating or simultaneous) from a single focal plane!

Versacorp, being primarily (but not being limited to) an engineering service business, has determined that it will offer licensing for its innovative immersive VR technology rather than orchestrating all production, integration and marketing of its many cutting edge product designs by itself. (However, appropriate special orders of prototype and production systems are welcome.) Where necessary, Versacorp can provide consulting services to assist licensees in implementing their custom applications. Please direct licensing or partnership related inquiries to the Technology Transfer Department: (license *at* versacorp.com).

By special arrangement, Versacorp can also work with the motion picture industry, theme parks, and others to provide custom Omnimmersion (TM, SM) productions and/or related infrastructure.

Return to Local Table of Contents

Technology Transfer Opportunities - Licensing Versacorp Technology

Versacorp, being primarily (but not being limited to) an engineering service provider, has determined that it will offer licensing for its innovative technologies or form appropriate partnerships, rather than constantly orchestrating all production and marketing of its many product designs by itself. Versacorp has 9 issued patents and over 100 patent claims are pending, with most being for wide angle imaging, VR environments, and related systems. Technology transfer opportunities for ultra wide angle optical systems and virtual reality environments include:

Return to Local Table of Contents

Immersive Imaging, Photographic or Motion Picture Capture, Display and Production, Other Services

Versacorp (SM) provides immersive imaging and other photographic capture and display services, including some of the areas that have been covered in Versacorp web pages since 1996. The founder of Versacorp, Jeffrey R. Charles, has periodically worked independently in professional photography since 1974, and in video production since 1991. Previous photographic works by Versacorp or its personnel include the fields of portraits, landscapes, astronomy, panoramas, architecture, resorts, conventions and other events, transportation, products, brochures, catalogs, news, and special effects. The first video produced was a 2 hour production covering the 1991 total solar eclipse in Mexico. With few exceptions, Versacorp (SM) imaging and production services are intended to be limited to content that would be equivalent to a G or PG movie rating.

Versacorp (SM, TM) also provides products and services in a wide range of fields, including engineering, conceptual architectural design, technical and screen writing, book editing, web page design, image processing, instrument repair, and more. In addition to marketing its own products, Versacorp also offers distribution and retail dealer representation for selected other manufacturers, having previoulsy been a dealer for Questar and Vernonscope.

Additional Versacorp products and services (some unrelated to imaging) include Nerdabilia (TM, SM) and VersaStuff (TM, SM). These Versacorp products and services include many diverse fields, including audio, books, cameras, music, surplus, and toys. Many of these items are listed in documents that are linked to the Miscellaneous Instrumentation Section of the Versacorp Home Page.

Please direct inquiries about any of the above to the Versacorp Sales Department (sales *at* versacorp.com).

Return to Local Table of Contents

Panoramic and Immersive Image Gallery

|

|

Additional photos can be seen at the Versacorp VersaGallery (TM, SM) Immersive Image Galery, via links in the following Recommended Reading, Cool Wide Angle Sites section, by referencing the Immersive Imaging and Technical Paper sections of the Versacorp web site, or by visiting www.eclipsechaser.com

Return to Local Table of Contents

Recommended Reading, Cool Wide Angle Sites

Sample images and recommended reading available at this web site or at Jeffrey R. Charles' award winning EclipseChaser web site:

Wide angle imaging papers by Jeffrey R. Charles:

Part 1: Converting Panoramas to a Circular Images and Vice Versa - Without a Computer! (60K text file with ~150K of images; more images may be added later). Abstract: This paper is based on a short article entitled "Converting Panoramas to Circular Images in the Darkroom", which Jeffrey R. Charles submitted to Astronomy Magazine in 1987 along with another article. They published the other article, but not this one. This article describes a process Mr. Charles implemented to produce the end sheet photo for the below 1977 yearbook reference. (What can now be done with software can also be done, and has been done, in the darkroom, but people would be crazy to do it in the darkroom now!) Jeff conceived, developed, & implemented the darkroom process (in this case, wrapping a straight panorama into a circle, though the same technique works in reverse) in 1976. The difficulty of this panoramic conversion task (combined with the fact Mr. Charles liked the resulting circular panorama for some applications) inspired him to invent various wide angle and panoramic systems, including the "Cassegrain" axial strut wide angle reflector.

Part 2: All-sky Reflector with "Invisible" Axial Camera Support (30K text file plus ~400K of linked graphics). Abstract: This paper shows and describes both prototyped versions of Mr. Charles' axial strut wide angle reflector and suggests many improvements. The original paper is published in the Proceedings of the 1988 Riverside Telescope Makers Conference.

Part 3: Techniques for Wide Angle Total Solar Eclipse Photography (30K text file with ~250K of images). Abstract: This paper explores the trades between many different panoramic and omnidirectional imaging methods as they apply to the critical task of imaging one's surroundings during a total solar eclipse - one of the most dynamic light shows in nature! Images of Mr. Charles' prototype axial strut reflectors which appeared in the August 1986 issue of Sky and Telescope Magazine are shown in the beginning of this article. Various parts of this paper were produced between 1986 and the present time. The paper also deals extensively with real time pixel reassignment and active digital image processing for predominantly linear sensor arrays which may be used on rotating cameras.

Examples of Circular and Rectangular Omnidirectional Images and How to Use Adobe Photoshop to Quickly and Easily Convert a Circular Image to a Rectangular Panorama. (10K text file with ~150K of images)

References to printed wide angle material by Jeffrey R. Charles are listed below. Most of the referenced magazine articles cover versions of the axial strut wide angle reflector which Mr. Charles originally built for his own use.

Whispering Pine '77 "Peaks and Valleys" (1977 Estes Park High School Yearbook), photo on End Sheet consisting of a 360 degree linear panorama which was converted to an ultra wide 360 degree annular photo of the entire horizon (and about 20 degrees above and below the horizon) in the darkroom. A short description of the process (some aspects and subsequent improvements covered in U.S. Patent 6,333,826) is in the paper entitled "Converting Panoramas to Circular images and Vice Versa - Without a Computer!" which is based on a short unpublished article Jeffrey Charles wrote in 1987 entitled "Converting Panoramas to Circular Images in the Darkroom". The URL is: http://www.eclipsechaser.com/eclink/astrotec/panconv.htm

Sky and Telescope magazine, August 1986, page 186. This reference shows Mr. Charles' early prototypes for both of his wide angle reflector designs. These first prototypes were made from simple materials. The common aspect of both versions is the use of an axial strut to support the camera and/or the reflector. Jeffrey R. Charles is the first and sole inventor of this means of camera and reflector support for a "Cassegrain" wide angle reflector and other embodiments where the strut originates relatively near the taking lens and is made thin enough to be "invisible" in the picture.

Astronomy Magazine, April 1987, article on pages 64-70, (Particularly pages 68 and 69.) "How to Build and Use an All-Sky Camera". This article only shows the version of Jeff's axial strut invention with the camera on top, but the original draft he sent the publisher included a lot more material. This draft is the basis for some documents on the Versacorp web page which are referenced above. Since the magazine article was about photographing the sky instead of the horizon, Jeff's two reflector design was not included by the editors, owing to its larger central obstruction. After the magazine's editors got through with the text, all that made the final article was this statement on page 66: "Yet another possibility (for an all-sky reflector design) is an "inside-out Cassegrain" all-sky camera. The camera goes behind the convex mirror and looks through a plastic window. A spacer rod is installed between the center of the window and the middle of a flat secondary mirror. This design is not only free from obscuration from support rods but is also very compact. It is admittedly the most difficult type to construct and also suffers from a bigger central obstruction than the others." Jeff's original material that was left out of the publication (but which was later published in one of Jeff's independent papers) also addressed the use of a curved secondary mirror such as that used on the Versacorp T11 axial strut wide angle reflector.

U.S. Patent D312,263. "Wide Angle Reflector Attachment for a Camera or Similar Article" Jeffrey R. Charles, Inventor; Filed in 1987, Issued Nov. 1990. This patent is primarily for IMPROVEMENTS over the prior disclosures of wide angle reflector prototypes which had been constructed by Jeffrey R. Charles (i.e. the patent deals with his prototypes as "prior art" and covers embodiments that are more desirable for commercial use than his original prototypes). The patent covers two embodiments of the invention: A "Cassegrain" version in which the secondary reflector is supported by an axial strut; and, a version in which a single convex reflector supported directly in front of the camera by means of an axial strut.

Proceedings of the 1988 Riverside Telescope Makers Conference, page 74. Portable All-Sky Reflector with "Invisible" Camera Support. There were over 600 people in attendance when Jeffrey R. Charles presented this paper in 1987. This paper shows and describes both prototype versions of Jeff's axial strut wide angle reflector and suggests many improvements. It also addresses aspheric reflector figures and reflector materials including glass, and metal, and plastic. Specifically mentioned are and plated metal reflectors, projector bulb reflectors and metalized plastic reflectors. A copy of this paper (sans most images but with some added comments in the first section) appears at the versacorp.com web site. Its URL is: http://www.versacorp.com/vlink/jcart/allsky.htm

A peripherally related subject involves the application of some of Jeff's ideas to other disciplines (such as antenna design) while an engineer at the Jet Propulsion Laboratory from 1992 to 1995. Most of this work is summarized in his "Airborne Large Aperture Telescope" (ALAT) paper, which is published in a relatively obscure JPL/NASA publication. An executive summary of the ALAT paper (HTML sans illustrations, but PDF has illustrations) is in the technical papers section of the Versacorp web site. All ALAT material was generated with Jeff's own time and resources, so he retained all intellectual property rights.

U.S. Patent 6,333,826. "Omniramic Optical System Having Central Coverage Means Which Is Associated With A Camera, Projector, Or Similar Article." Jeffrey R. Charles, Inventor; Filed in 1998 (claims benefit of 1997 provisional application), issued Dec. 2001.

U.S. Patent 6,449,103. "Solid Catadioptric Omnidirectional Optical System Having Central Coverage Means Which Is Associated With A Camera, Projector, Medical Instrument, Or Similar Article" Jeffrey R. Charles, Inventor; Filed in 1998 (claims benefit of 1997 provisional application), issued Sep. 2002.

An additional utility patent encompasing over a hundred claims for Mr. Charles' wide angle technology is pending.

Have wide angle imaging needs which are not addressed in this material? Versacorp offers custom products and appropriate engineering services.

Wide angle imaging papers by other authors available on the Internet:

Spherecam technical paper by Dan Slater. The Spherecam is an omnidirectional imaging system consisting of two cameras, each equipped with 220 degree fisheye lenses. The cameras are mounted on a pistol grip assembly and point in opposite directions. The Spherecam paper also includes information about image processing which can be used to combine the raw fisheye images and convert them into straight panoramas and other projections. It has recently been updated to include Photoshop compatible macros for some of the techniques. Some of these image processing techniques can be applicable to images taken with wide angle reflector systems.

Wide angle imaging papers by other authors available in printed form:

Brevet D'Invention, (French Patent) No. 1.234.341; Baltes; 10/1960 354/94. Probably the very first axial strut reflector, this patent is for a single reflector which faces the camera. It is supported by a short axial strut which extends from an optical window; the optical window being much closer to the reflector than it is to the camera's taking lens. Some of the technology not covered by existing and pending Versacorp patents can be gleaned from this reference. Patented Versacorp axial strut wide angle reflector designs typically place the end of the axial strut substantially closer to the camera lens (and appropriately reduce the strut diameter) in order to achieve compactness, increase the AOV, and make it possible to implement a "Cassegrain" design.

Unusual Telescopes (A book by Pete Manly) page number unknown. A photo of Jeff's first amateur version of the axial strut reflector (originally made in 1977 and modified to utilize a L'eggs "Sheer Energy" metalized hose egg in 1978) is in this book. The author made errors in the book about conception of the invention, attributing it to two people. Mr. Charles both told and wrote the author about this, but said author failed to correct the error before publication.

© Copyright 1997, 1998, 1999 (Reg. Copyright 1999), 2002, 2003,

2004 Jeffrey R. Charles. All Rights Reserved.

The trademarks (and service markes or trade names, as indicated) DiaGuider

(TM, local use 1983, first interstate and international use 1984),

EZ Level (1997), Jeffrey R. Charles (TM, SM 1974), Jeffrey R. Charles

Productions (1995), JRC Designs (TM, SM 1980), JRC Productions (1991),

MicroDec (1987), MicroStar (1988), MicroTrack (1987), Nerdabilia (1996),

Omniflector (1997), OmniGallery (2004), OmniLens (1988), Omnimmersion (1998),

Omnimmersive (1998), Omnirama (1997), Omniramic (1997), Omniramix (1998),

OmniSales (1997), OptiDisc (1987), Sun Zapper (1997), The Reality of Virtual

Reality (1997), Total Immersion (1997), Total Immersion VR (1997),

Total VR (1997), Versacorp (TM, SM, TN, 1983, interstate and international

use in many fields since 1984), versacorp.com (TM, SM, 1996), VersAdapter (1983),

VersaDrawer (1987), VersaFinder (1987), Versaflector (1997), VersaFocus (1985),

VersaGallery (2004), VersAgonal (1984), VersaGuider (1984), VersaJeff (1999),

VersaModule (1983), Versarama (1997), VersaScope (telescopes 1987, other optics 1997),

VersaStuff (2004), VersaWheel (1990), VidFinder (1990)

and associated concepts, data, designs, images, and other elements shown and

described in this or related documents are the sole property of Jeffrey R. Charles.

All content is protected by intellectual property laws. Any form of

reproduction or posting of any part of this or any associated document

at web sites other than "eclipsechaser.com" or

"versacorp.com", or any commercial use (such as in a seminar,

product, program, publication, broadcast, or motion picture) of data or

other material in this web page, or of related material by the same author

(whether said material was obtained directly or indirectly) without including

this notice and without the prior express written consent of Jeffrey R.

Charles is strictly prohibited. Any use other than for private, individual,

non-commercial purposes is strictly prohibited. Unauthorized use is subject

to being prosecuted to the full extent of the law. Use of this material is

subject certain additional Terms and

Conditions. In downloading material from this web page or transferring

said material from a cache, you are deemed to have agreed to these terms

and conditions. For information about the purchase of products and/or

the license or purchase of designs, images and/or articles or related

book, movie, patent, or technology rights, please contact Jeffrey R. Charles.

Versacorp has existing and pending patents for some of the items described in this document, and Versacorp typically enforces these patents for commercial vendors, users, applications, government contracts, etc., but can presently (under certain conditions) grant exceptions for certain amateur noncommercial use by private individuals; however, any exceptions for amatuer or other use are subject to change without notice. Versacorp may grant a free limited license to an individual to build and use one axial strut reflector system under the following conditions: An individual is currently allowed to build one axial strut reflector system (as shown and described in Jeffrey R. Charles' previous (1988 and earlier) amateur wide angle reflector papers (but typically not items covered under more recent U.S. Patents 6,333,826 and 6,449,103) for his/her own private non-commercial and nonprofit use, provided that said individual affixes a label to the system which includes the statement: "U.S. Patent D312,263 and Patent Pending by Jeffrey R. Charles. All rights (including commercial and intellectual property rights) reserved. Used by permission of Jeffrey R. Charles." and specify the same in any publications or public presentations relating to the subject systems. Versacorp obviously desires the business of hobbyists and other individuals, but Versacorp also wants individual amateur "do it yourselfers" to enjoy the benefits of this segment of its technology. Versacorp and any licensees who obtain exclusive rights to the related technology reserve the right to stop granting licenses to individuals, nonprofit groups, or any others at any time. The above patent notice is not necessary if the constructed embodiment is exactly like one of Jeffrey R. Charles' pre-1987 prototypes which were the subject of publications up to and including August, 1986, since those particular two prototypes are not patented. (However, it would be appreciated if people who build a copy of any of these prototype units acknowledge Mr. Charles as the inventor. Photos of these early prototypes are published in some of the amateur papers which are at or linked to the Versacorp web site.) Again, Versacorp typically enforces its patents in regard to commercial vendors, users, applications, government contracts, etc.. Versacorp and its founder also reserve the right to enforce the patents in other cases where a substantial quantity of units are made, sold, or used without authorization and/or without the payment of prescribed, reasonable, or suitable royalties. All rights (including commercial and intellectual property rights) reserved.

Send Non-Spam E-mail to: Jeffrey R. Charles at Versacorp (jcharles *at* versacorp.com).

Text Last modified: 15 Feb., 2004

Amateur Use Conditions modified: 11 Dec. 1997

Links Last Modified: 20 March, 1998

Specifications Last Modified: 1 May, 1998